Flat Die Pellet Mill and Ring Die Pellet Mill

Many of us are familiar to ring die pellet mill because in domestic and international numerous feed enterprises are using it. In order to guide the customer in choosing pellet mills more faciliable, we made a comprehensive comparison of flat die pellet mill and ring die pellet mill.

|

|

| Flat die pellet mill | Ring die pellet mill |

|---|

- Feeding way, ring die adopts machine forced feeding and the feeding is uneven while the flat die pellet mill depends on the materials’ weight vertical entering the suppress room, and it can ensure steady feeding.

- Pressure. Flat die pellet mills can increase inside outfit bearing space so that it not only improve the pressure also increase the life while the ring die’s pressure is limited.

- Discharging way. The ring die pellet mill belongs to high rotary way and the material damage rate is very high. To the contrary, the flat pellet mill has a rotary way, so its damage rate is comparatively low.

If you want to know more about flat die pellet mill and ring die pellet mill, please feel free to contact us.

Product List

COMMENTS

Charles Avery

AUS

Kelly Kulp

USA

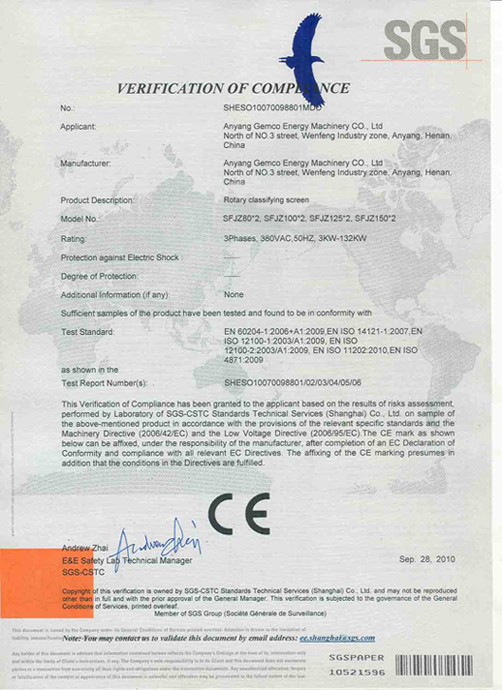

AGICO GROUP © Copyright 2012 | Privacy policy Anyang Gemco Energy Machinery Co.,Ltd E-mail: sales@chinapelletmill.com