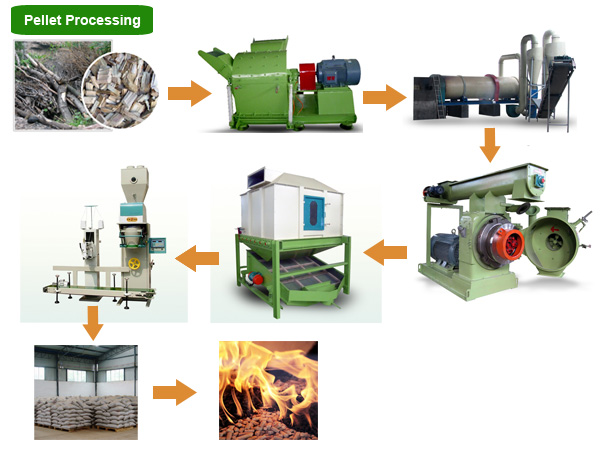

Pelletizing Process

Pelletizing process of compressing or molding materials into the shape of a pellet. A wide range of different materials can be pelletized. While before pelletizing, there are several notes to consider:

1. Size: Chippers/Shredders, Hammer Mills

2. Materials convey: Fans, Cyclone Separators and Screw Augers

3. Dryer: Rotary/Drum Dryers, Pipe Dryers

4. Mixing: Batch Mixers

5. Conditioning: Water and Steam Addition, Binders

6. Pellets size: Round and Flat Die Pellet Mills

7. Sieving: Removing Fines

8. Cooling: Counter Flow Coolers

9. Packing and Storage: Bags, Sacks and Silos

GEMCO is a main manufacturer of pellet mill and guider for pelletizing process. High quality,best service. We also receive orders for customers requirements, which include flat die pellet mill, ring die pellet mill, electric pellet mill,wood pellet machine etc.