Complete Wood Pellet Plant

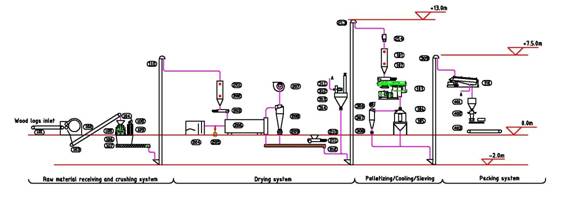

Flow chart:

The medium and large sized wood pellet plant usually include the Wood chipper, Crusher, Dryer, Hot blast stove, Wood pellet mill, Cooler, Sieve machine, Packing machine, sealing machine, screw conveyor, belt conveyor etc. These machines are divided into four parts as follows:

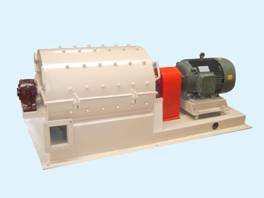

1. Crushing system

There are wood chippers and hammer mills in the crushing system of pellet plant are choosen according to the size of your raw materials.

The wood chipper is used to crush the wood logs into small size wood chips. The Hammer mill used to crush the wood chips into sawdust for pelletizing.

|

|

|

|

|

|

2. Drying system

The best moisture of your raw material for pelletizing is 15%. For wood pellet plants with capacity more than 1t/h, we suggest you use the rotary dryer. This rotary dryer needs to be matched with the hot blast stove which used to offer hot air for the rotary drum.

|

|

|

|

|

|

3. Pelletizing system and Cooling system

The pelletizing system used to process sawdust after crusher and dryer process above. The size of wood pellet is 6mm or 8mm usually. There are two kinds of wood pellet mills, one is gear drive and another is belt drive.

After the pelletizing process, the temperature of the wood pellet is about 60-80 degree, and the moisture content of the wood pellet is about 15%, so we need use the Cooler to reduce about 3-4% moisture. The wood pellet is easy to store.

|

|

|

|

|

|

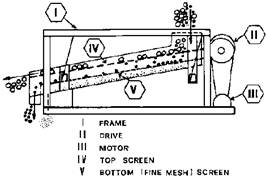

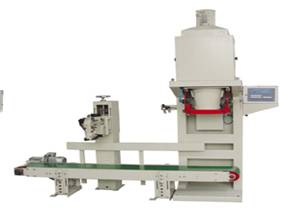

4. Sieve and packing system

The sieve machine is used to select quality standard wood pellets and get rid of the small size pellet.

For easy storage and sale, the wood pellet is often packed into the plastic bags. It can void humidity and broken pellets.

|

|

|

Small Pellet Mill

- For Different Models

- For Different Materials

Large Pellet Mill

Biomass Pellet Plant

Auxiliary Machinery