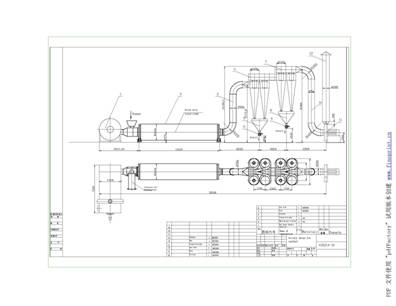

Rotary Dryer

The rotary dryer is used to reduce the moisture content of the raw materials before pelletization. The machine was designed to work continuously and automatically, and includes a rotary dryer, screw feeder, cyclone air system, air lock and fan.

The wet material enters the dryer through the feeder in controlled quantities. A rake inside the cylinder distributes the material uniformly in the dryer for maximum exposure to the current of hot air. After traversing the length of the dryer the material is discharged through a star valve at the end at the perfect moisture content.

|

|

|

Technical parameters:

| Model | Volume (m3) |

Power(kW) | Reducer | Air fan | Cyclone | Outside dimensions (mm) |

Weight(t) |

| HZG1000X10 | 7.85 | 4.0 | JZQ400 | 4-72№6C 7.5 | φ900 | 10000X1876X2069 | 7.5 |

| HZG1200X8 | 9.1 | 5.5 | JZQ500 | 4-72№6C 7.5 | φ900 | 8000X2159X5475 | 8.75 |

| HZG1200X10 | 11.31 | 7.5 | JZQ500 | 4-72№6C 11 | φ900 | 10000X2159X2475 | 9.25 |

| HZG1500X10 | 17.7 | 7.5 | JZQ500 | 4-72№6C 15 | φ900 | 10000X26556X2895 | 15.9 |

| HZG1500X12 | 21.2 | 7.5 | JZQ500 | 4-72№6C 15 | φ900 | 12000X2055X28959 | 17.13 |

| HZG1500X14 | 24.9 | 7.5 | JZQ500 | 4-72№10C 18.5 | φ1100 | 14000X2655X2895 | 18.33 |

| HZG1500X17 | 30.2 | 11 | JZQ500 | 4-72№10C 18.5 | φ1100 | 17000X2655X2895 | 19.50 |

| HZG1800X12 | 30.5 | 11 | JZQ650 | 4-72№10C 18.5 | φ1100 | 12000X3060X2980 | 19.89 |

| HZG1800X14 | 35.1 | 11 | JZQ650 | 4-72№10C 18.5 | φ1100 | 14000X3060X2980 | 20.85 |

| HZG1800X18 | 45.8 | 15 | JZQ650 | 4-72№10C 30 | φ1500 | 18000X30609X2980 | 22.3 |

| HZG2200X14 | 53.2 | 15 | JZQ750 | 4-72№10C 30 | φ1500 | 14000X3620X3570 | 32.23 |

| HZG2200X20 | 70 | 18.5 | JZQ750 | 4-72№10C 37 | φ1500 | 20000X3620X3570 | 36.07 |

| HZG2400X18 | 81.3 | 22 | JZQ850 | 4-72№12C 55 | φ2000 | 20000X3860X3760 | 48.2 |

| HZG2400X20 | 90.4 | 22 | JZQ850 | 4-72№12C 55 | φ2000 | 18000X3860X3760 | 52.0 |

The rotary dryer may also require a hot blast stove as a source of hot air. The stoves fuels can be the same biomass materials—wood, wood pellets, straw, etc.—bound for pelletization.

Small Pellet Mill

- For Different Models

- For Different Materials

Large Pellet Mill

Biomass Pellet Plant

Auxiliary Machinery