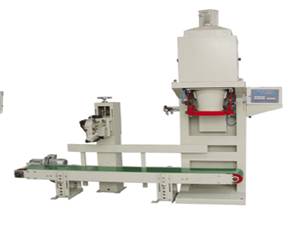

Packing Machine

Packing is the final process in pellet production. This machine comprises of storage bins, automation system, and a sealing machine.

An automatic system includes computer controlled system, where the finished feed is weighed by the computer. Then it can discharge the pellet into the bags in a certain weight. There is also a conveyor with the sealing machine which can move the bags.

|

|

|

1. Technical Parameters:

|

Precision |

+/-0.2% |

|

Packing speed |

100~200bags per hour |

|

Weighing scale |

10kg-30kg per bag |

|

Power Supply |

220Va.c and 4N-380Va.c |

|

Power Dissipation |

1.5kW |

|

Compressed Air |

0.4MPa0.6MPa |

|

Compressed Air Consume |

0.5m3 per hour |

Main Structures:

3.1 Auto filling system

3.2 Auto weighting balance

3.3 Auto belt conveyor

3.4 Semi-Auto Hot sealing Machine(By foot switch)

3.5 Electronic control cabinet and Computer Control cabinet

4.Flowing Process:

Manual bag placing-->Auto filling-->Auto weighting-->Auto bag discharge-->Auto bag conveyor-->Semi-Auto Bag hot sealing

5.Key Parts:

|

NO. |

Parts |

Type |

Brand |

Product country |

|

1 |

Weight sensor |

IL-250kg |

Mettler-Toledo |

USA |

|

2 |

Material Level Sensor |

CS-16-5T |

KOYO |

JAPAN |

|

3 |

Cylinder |

ST /CB |

AirTac |

TAIWAN |

|

4 |

Magnetic valve |

MV220-4E1 |

||

|

5 |

oil-water seperator |

UFR/L04 |

||

|

6 |

controller |

DCS25 |

|

|

Small Pellet Mill

- For Different Models

- For Different Materials

Large Pellet Mill

Biomass Pellet Plant

Auxiliary Machinery