Biomass Briquetting Plant

Due to the increasing cost of conventional fuel(such as coal,oil and natural gas etc.) and the need for new energy resources, more people start to focus on Biomass fuel business. It has become more and more important for companies to find low-cost methods of recycling their waste materials such as wood, straw, rice husk,peanut shell, sunflower seed husk etc. This is especially true if these waste materials have a high energy content and we want to take them back into the energy cycle.

|

|

|

|

Briquetting Press Model ZBJI |

Wood Briquettes made from Briquetting Press

|

Anyang general international Co.,Ltd is a leading company for screw type briquetting plant in China and has exported to more than 20 countries all over the world from 1996, especially in east European countries and South-eastern Asian countries, where our briquette machines are popular for small private users.

Our briquetting plant is designed for small scale biomass briquettes production, it can make hollow hexagonal or quadrangular cylinder with a 15-20mm hole through the body. Diameter of briquettes range from 30mm-100mm.In the briquetting process, no binder or chemicals need to be used, so the final briquettes are renewable, clean, eco-friendly. The density of briquettes made at our machines is 1100~1300kg/CBM. Owning to their great density, wood briquettes have a higher calorific value than the same quantity of firewood. They can be used to replace conventional fuels in domestic solid-fuel stoves as well as in industrial furnaces. Burning a wood briquette is far more efficient than burning firewood. Moisture content of a briquette can be as low as 4-5%%, where as green firewood may be as high as 65%.

Raw Material to make Biomass Briquette include:

Any type of Agro-Forestry waste can be used. But the Moisture Content Should be about 8-12%, grain size is below 5*5mm.

Saw dust • Wood Chips • Wood logs • Tree branch • Wheat Straw • Peanut-shell • Rice husk • Sugar Cane Bagasse • Coffee Husk • Paddy Straw • Sunflower Seed Husk • Sunflower Stalk • Reeds • Cottonplant Stem • Tobacco waste • Mustard Stalk • Jute waste • Bamboo Dust • Tea waste • Palm husk • Soybeans husk and many other agro and forest wastes.

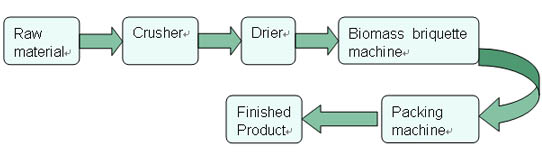

Process of Briquetting:

1. Wood Straw Crusher:

Crushing machine prepare suitable size raw material for biomass briquetting plant. The requested size for briquetting is 3-5mm.The choice on crushing machines depend on the types and sizes of raw materis.

Hammer mill is to crush small sized material with diameter no more than 50mm, such like tree branck, tree trimmings, wood chips, wood cuttings, cotton stalk, corn stalk, wheat straw etc. Blate type wood crusher is to crush wood logs with diameter less than 200mm to 3-5mm at any length.

2. Briquetting Plant Dryer

Drying machine prepare suitable moisture raw material for biomass briquette press. Moisture of raw material is important for making good briquettes. The proper moisture of raw material should be 8-12%. The choice on dryer model depend on the original moisture content of raw materials.

3. Briquetting Press

Biomass briquetting press make the biomass material into briquettes. After the well preparement of raw metarial, briquetting is easy to operation of biomass briquette press. When machine rise to over 300 centigrade, the material can be feeding continuously into briquetting press. First, the color of briquettes may be a little dark even black, but after a while, the color will be light to normal level coming out of biomass briquette machine.

4. Packing Machine

Packing machine pack final biomass briquettes for commercial reselling. They can be wrapped with a layer of plastic film. By thermal shrink wrapping machine, biomass briuqttes can be packing into a bundle tidily.